| Specifications | |||||||

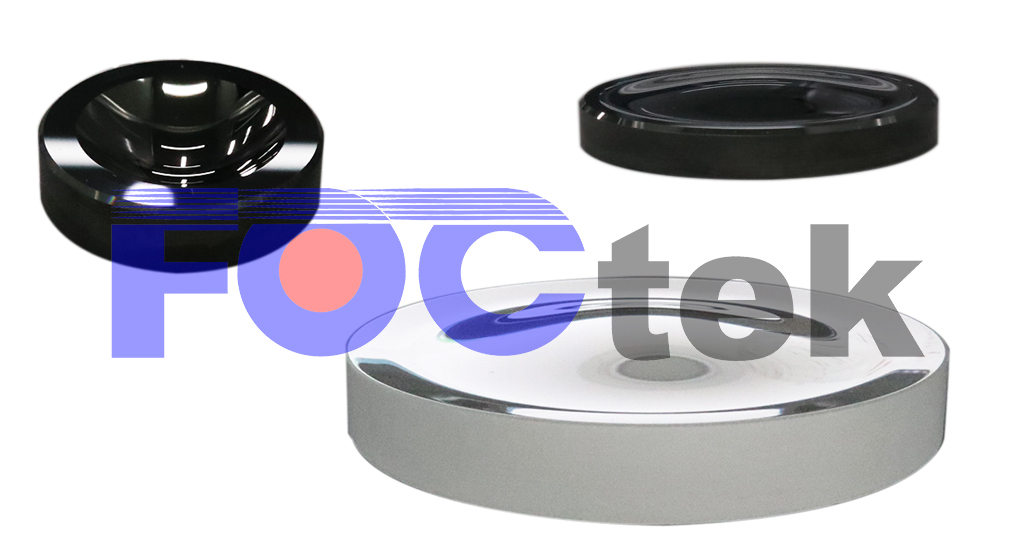

| Aspheric Lens | Material | Size(mm) | Surface Error | High Precision Surface error | Surface Quality | High Precision Surface Quality | Center deviation |

| Si、Ge、Al、Cu | 5~200 | PV<0.2μm, RMS<0.02μm |

PV<0.15μm, RMS<30nm |

Ra<5nm | Ra<3nm | ≤1' | |

| Chalcogenide Glass, Crystal, Plastic | PV<0.2μm, RMS<0.02μm |

PV<100nm, RMS<20nm |

Ra<3nm | Ra<0.5nm | |||

| Optical Glass, Quartz Glass, Sapphire, etc. | PV<0.2μm, RMS<0.02μm |

PV<100nm, RMS<20nm |

Ra<3nm | Ra<0.5nm | |||

| PS: Provide various coating solutions. | |||||||

Copyright © 2020 Foctek Photonics, Inc. All Rights Reserved All Rights Reserved 闽ICP备05011100号

Power:BAINANET

sales@foctek.com

sales@foctek.com